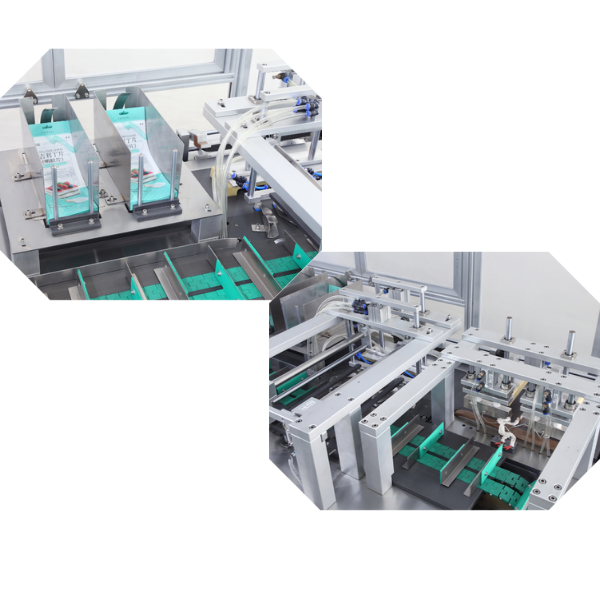

Multifunctional Horizontal Pouch Packaging Machine

The TD1-200 horizontal multi-functional bag-filling and sealing machine is an automated bagging and sealing equipment developed by our company’s R&D department specifically to meet market demands, replacing manual labor. This equipment has a wide range of applications and can replace manual labor for automated production in industries such as hardware, food, pharmaceuticals, cosmetics, and medical devices. The machine is easy to operate, reducing labor costs while increasing production capacity.

The machine uses a PLC programmable controller and is operated through a human-machine interface, making operation more user-friendly. The equipment is simple to operate and highly stable. It features a material detection system that ensures bags are filled and sealed at the correct position, effectively preventing waste of packaging bags.

- Multi-functional Compatibility: Compatible with various packaging bags made of composite film, kraft paper, stand-up pouches, and other materials; supports packaging of granular, powder, liquid, and block materials, meeting the needs of food, chemical, daily necessities, and other industries.

- High-efficiency Automation: Automatically completes the entire process of bag picking, opening, filling, sealing, and coding. Single bag processing speed can reach 10-60 bags/minute, significantly reducing labor costs.

- Precise and Stable: Adopts a servo control system, with a bag picking positioning error of ≤±1mm, filling accuracy of ±0.5%, and uniform sealing temperature (error ≤±2℃), ensuring product consistency.

- Intelligent and Convenient: Equipped with a touch screen operation interface, supporting parameter storage (can store 50+ recipes), automatic fault alarm, and bag/material shortage reminders, making maintenance simple.

- Durable and Easy to Maintain: The parts in contact with materials are made of 304 stainless steel, which is corrosion-resistant and easy to clean; modular design allows for quick disassembly and replacement of core components, adapting to different product specifications.

- Safe and Compliant: Complies with food machinery safety standards, equipped with emergency stop buttons, protective fences, and anti-scalding sealing design to ensure operational safety.

| Production Capacity | 20-50 bags/minute (depending on the product) |

| Total Power | 5KW |

| Heating Power | 1.0KW |

| Operating Voltage | 220V(50Hz) |

| Working Pressure | 0.5-0.8Mpa |

| Packaging Bag Dimensions | Length (230-270) * Width (70-150) |

| Packaged Product Dimensions | Length (100-250) * Width (50-130) * Height (5-30) |

| Equipment Dimensions | Length 3700 * Width 1100 * Height 1750 (Dimensions may vary depending on the specific model) |