Applicable Industries

This equipment is widely applicable to the packaging of food products (bread, chocolate, dried persimmons, biscuits, lollipops, etc.), daily necessities (syringes, pens, bottles, books, knives, forks, spoons, soap, towels, etc.), medical supplies (masks, gloves, protective clothing, hats, etc.), and hardware and daily chemical products (screws, switches, sockets, chargers, data cables, etc.).

The equipment features a compact structure, stable performance, and simple operation.

It has a self-diagnostic function for malfunctions, with clear fault displays, making maintenance and servicing more convenient.

The product packaging has a high pass rate and a beautiful seal, significantly improving efficiency and reducing labor costs for customers.

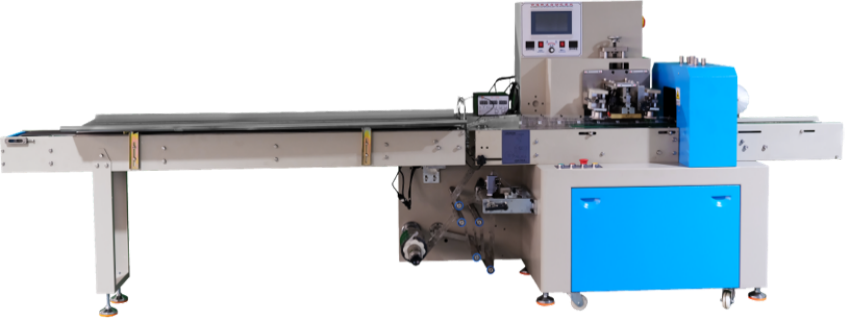

This bottom-feeding pillow-type packaging machine features a three-servo drive system with independent control. It includes feed detection, empty bag prevention, and anti-cutting functions; the conveying method is adapted to the material being transported.

Automatic positioning and feeding are available, and it can be connected to different material conveying systems for material identification;

The machine features a stainless steel structure,

with a sleek and aesthetically pleasing design, and is easy to operate; it utilizes high-sensitivity photoelectric color mark tracking.

Digital input of the sealing and cutting position ensures greater accuracy.

It can simultaneously handle packaging of multiple product specifications, with convenient adjustment.

Optional functions such as coding and inkjet printing are available.

All controls are implemented through software, facilitating function adjustments and technological upgrades, ensuring it remains up-to-date.

| Model | XL-350X | XL-450X |

| Membrane Width | Maximum340mm | Maximum440mm |

| Bag Length (belt end bracket, no maximum length limit) | Double swords(Push rod tail bracket)60-190mm 90-220mm Single sword(Push rod tail bracket)120-280mm 150-330mm | Push rod tail bracket:180-450mm Belt tail frame:180-(Longest without limit) |

| Bag Width | 50-160mm | 80-200mm |

| Product Height | The lower blade has a maximum height of 45mm, and the upper blade has a maximum height of 60mm. | 80-100mm |

| Maximum Film Roll Diameter | Max320mm | Max320mm |

| Packaging Speed | 5-25 meters/minute(Belt tail frame) 40-230 bags/minute(Push rod tail bracket) | 5-25 meters/minute(Belt tail frame) 40-80 bags/minute(Push rod tail bracket) |

| Power Supply Specifications | 220v.50/60HZ.2.6KW | 220v.50/60HZ.2.8KW |

| Machine Dimensions | 3533*765*1312mm(Belt tail frame) 4011*765*1312mm(Push rod tail bracket) | 3594*860*1100mm(Belt tail frame) 3744*860*1100mm(Push rod tail bracket) |

| Machine Weight | 350kg | 450kg |

Equipment Schematic Diagram