This equipment can automatically complete the entire process, including connection to the system, automatic feeding, filling, bag making and sealing, batch number printing, weighing and packaging, and finished product output!

Utilizing a servo system motion controller,

dual encoder electronic pulses control sealing and cutting, paper feeding, bag making, and forming.

Bag length is set and cut instantly, color mark tracking is precise and efficient, and the machine stops automatically in case of material shortage or empty bags, preventing miscuts. Suitable for packaging large-sized products such as large chocolates, biscuits, multi-pack sachima,

multi-pack baked goods, and potato chips.

| Packaging Speed | 30-80 bags/minute (depending on product size) |

| Packaging Specifications | Length 150-450mm, width 200mm, height 120mm |

| Scope Of Packaging Materials | 300-600mm |

| Applicable Packaging Film Materials | OPP、PE、PVC、OPP/CPP、PT/PE、KOP/CPP |

| Equipment Power | 10KW |

| Control System | PLC control system, touch screen display |

| Power Supply | 220V/380V50HZ/60HZ |

| Equipment Dimensions | 4288*1243*1510mm |

| Equipment Weight | 1500kg |

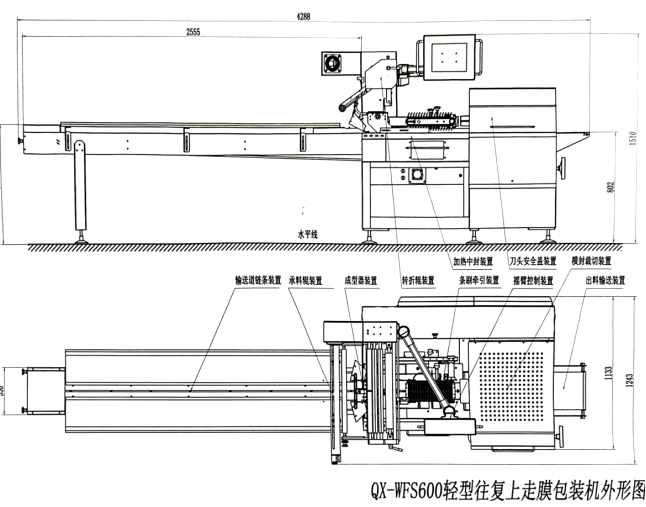

Equipment Schematic Diagram