Applicable Industries

Pharmaceutical Industry:

Blister packs, oral liquids, ampoules, vials, sachet-packed granules, medicated patches, ointments, aerosol products, etc.

Food Industry:

Ice cream, egg rolls, bread, bagged coffee, seasoning sachets, milk powder, etc.

Daily Chemical Industry:

Toothpaste, soap, cosmetics, facial masks, face creams, lip balm, mosquito coils, etc.

Hardware & Electrical Industry:

Bearings, light bulbs, switches, sockets, relays, chargers, etc.

Automotive Parts Industry:

Spark plugs, filters, piston rings, automotive bulbs, automotive electrical components, etc.

Plastic Products Industry:

Plastic wrap, plastic products, etc.

Stationery, Toys & Gifts Industry:

Pens, staplers, ink pads, playing cards, puzzles, toys, handicrafts, etc.

Household Paper Products:

Facial tissues, sanitary napkins, panty liners, cotton pads, etc.

The multi-functional carton packing machine is the latest product developed by our company. It features a compact size, light weight, wide application range, high production efficiency, and multi-purpose functionality.

This machine can package items of various specifications and is suitable for food packaging, cosmetic packaging, and packaging in related industries. It has a wide range of applications and, depending on the user’s requirements, can be used for large-volume single-product production as well as small-batch multi-product production. The carton packing machine outlet can be matched with various types of medium-sized box film packaging equipment.

Safety:

No product: No box feeding, the entire machine automatically stops and sounds an alarm.

Product present: No carton (or the carton is not properly formed), the entire machine automatically stops and sounds an alarm.

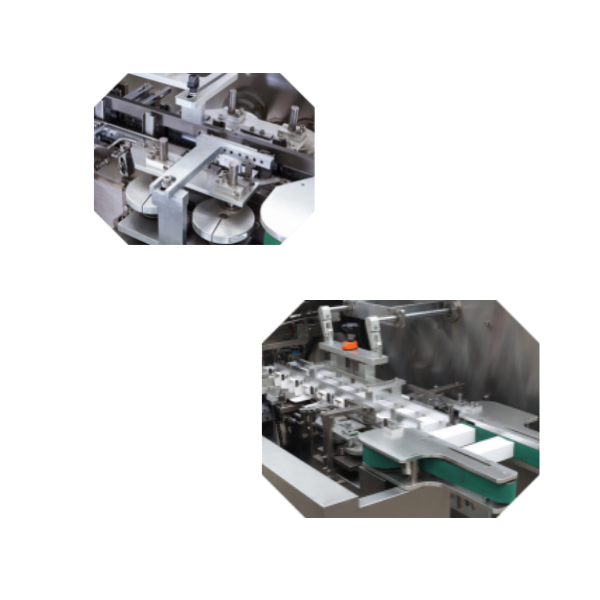

The carton packing machine operates intermittently, with PLC control, a simple structure, and easy maintenance. This machine uses a series of complex transmissions, mimicking human movements to automatically complete complex processes such as box feeding, box opening, and box sealing.

The overall carton packing speed is high, but the packaging material’s running speed is low, thus reducing the packaging material’s sensitivity to running speed, enhancing packaging material adaptability, and minimizing mechanical wear. Its characteristics are: high output and low mechanical running speed.

The vacuum system used in this machine is a ZL112 vacuum generator (SMC), with automatic vacuum box picking and large-angle box opening, ensuring the accuracy of box opening.

The box feeding system operates intermittently and is equipped with push-in overload protection to ensure safe item placement in the box (protecting both personnel and the machine).

This machine is easier to adjust and maintain. Various box closing methods and other devices are optional. When changing to different sizes of cartons, there is no need to change molds; simply adjust the positioning according to the box size.

The machine frame and panel have sufficient strength and rigidity. The main drive motor and clutch brake are installed in the machine frame, and the various transmission systems are installed on the machine panel. The torque overload protector can disengage the main drive motor and various transmission parts in case of overload, protecting machine parts from damage.

| Project | Parameter | Remark |

| Main Motor Power | AC 220V, three-phase five-wire, total power 1.5 kW. | |

| Packaging speed | 30-90 boxes/minute | |

| Power supply/Total power | 1.5KW | |

| Gas consumption | 20 m³/hour (pressure 0.5-0.8 MPa)) | |

| Cardboard box material requirements | White cardstock 250-350 g/m² Gray cardboard 300-400 g/m² | |

| Applications of cardboard boxes | Minimum size: 70*20*12mm Max size:220*120*60mm | Length * Width * Height |

| External dimensions | 3500*1400*1900mm | Length * Width * Height (including wooden crate) |

| weight | 1500kg |

1.It adopts an automatic packaging form including automatic feeding, box opening, product insertion, batch number printing, box sealing, and rejection of defective products, with a compact and reasonable structure and simple operation and adjustment;

2.It uses a servo/stepper motor and a touch screen, PLC programmable control system, and a human-machine interface display for clearer and simpler operation, resulting in a high degree of automation and greater user-friendliness;

3.It uses a photoelectric eye automatic detection and tracking system, preventing empty packages from being boxed, thus maximizing the saving of packaging materials;

4.It has a wide packaging range and is easy to adjust, allowing for quick conversion between various specifications and sizes;

5.Changing specifications does not require changing molds; it can be achieved simply by adjustment;

6.It features an automatic stop function if the product is not properly inserted into the box and an overload protection device for the main drive motor, making it safer and more reliable;

7.According to customer requirements, an upward-opening safety protective cover can be adopted, making operation convenient and the appearance aesthetically pleasing;

8.It can be linked with other equipment such as blister packaging machines, pillow packaging machines, three-dimensional packaging machines, bottling lines, filling machines, labeling machines, inkjet printers, online weighing instruments, and other production lines;

9.Various automatic feeding and box insertion systems can be designed according to the requirements of the packaged items;

10.According to customer requirements, a hot melt glue machine can be selected for hot melt glue spraying and sealing or mechanical brush glue sealing.

Technical Overview

1.The entire machine is designed and manufactured according to current GMP-compliant workshop space and layout standards.

2.Functional zones are clearly separated, and the machine adopts imported photoelectric sensors for tracking, inspection, and automatic control of operation.

3.After products are automatically loaded into plastic trays, the system completes fully automatic cartoning and box sealing.

4.All mechanical stations operate with high electronic synchronization, ensuring smoother and more balanced performance with low noise levels.

5.The cartoning machine is easy to operate, featuring PLC programmable control and a touchscreen human–machine interface (HMI).

6.The PLC automation control system provides output interfaces that enable real-time monitoring of downstream packaging equipment.

7.The machine offers a high level of automation, a wide control range, high control accuracy, fast response, and excellent operational stability.

8.With fewer components and a simple mechanical structure, the machine is easy to maintain and service.

9.Low-noise design, with operating noise ≤ 75 dB.

10.Maximum production speed: 100 cartons per minute; stable operating speed: 30–100 cartons per minute.

11.The entire line is equipped with threaded adjustable leveling feet, allowing flexible height adjustment.