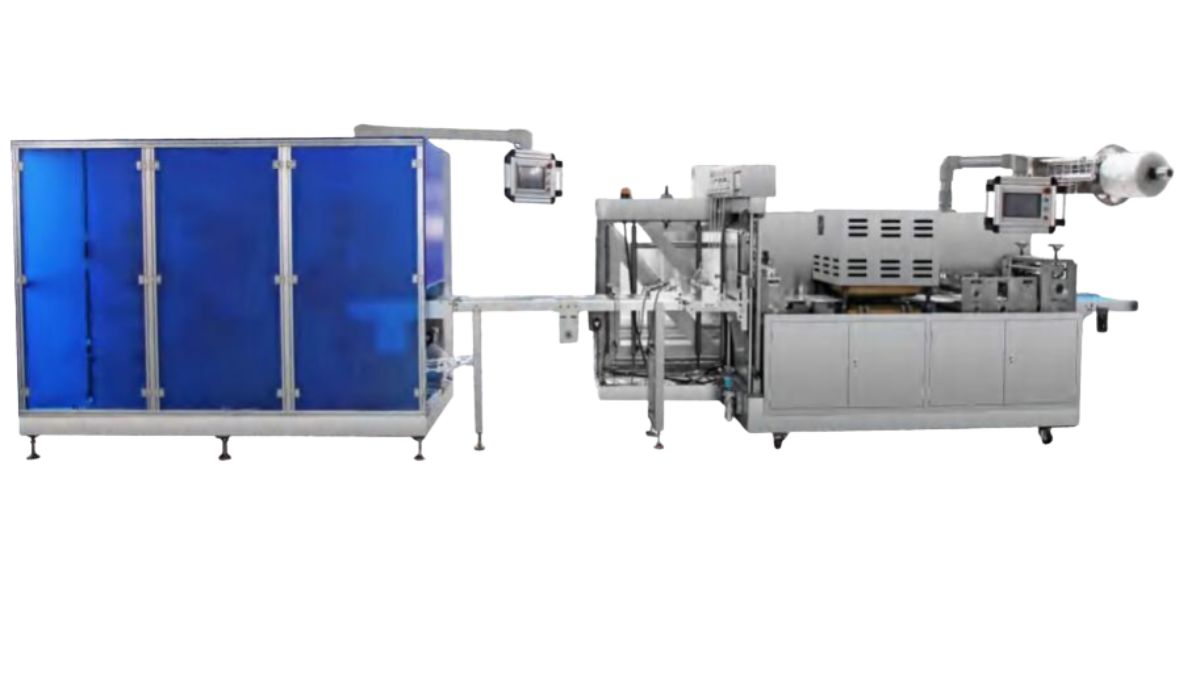

This machine features advanced functions, simple operation, and high output, making it the ideal packaging equipment for the cosmetics, health products, food, and household goods industries.

Main performance And Structural Characteristics

The SBF800 single-film continuous automatic four-side sealing eye mask packaging machine is a newly upgraded and improved equipment launched by our company. It adopts servo motor planetary reduction and integrated control technology combining mechanical, electrical, optical, and pneumatic systems.

Main functions: automatic film feeding, automatic bag making, automatic material dispensing and filling (optional), graphic alignment, automatic coding (batch number printing), flat pressure heat sealing, easy-tear opening and hanging hole punching, rotary knife cutting, finished product output, and waste material recycling.

| Production Capacity | 160-240 packs/minute (depending on product size) |

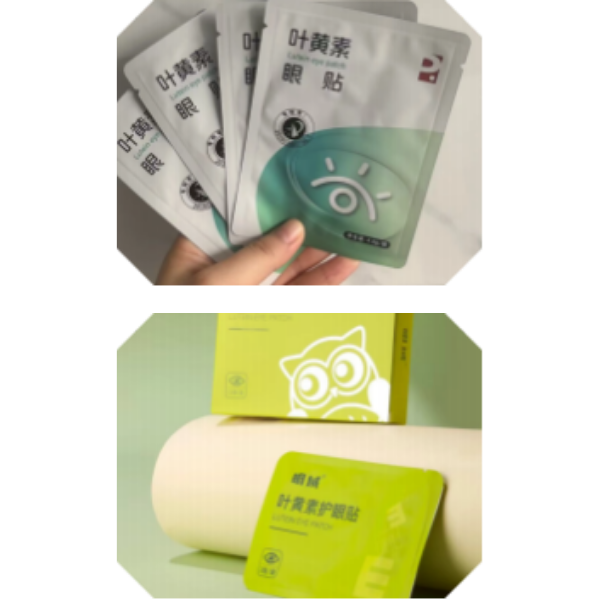

| Maximum Bag Size | 180mm wide * 300mm long (customizable according to product requirements) |

| Minimum Bag Size | Width 100mm * Length 150mm (Customizable according to product requirements) |

| Packaging Materials | 5 rolls of film with thickness (0.03-0.12), maximum width 450mm, roll diameter 350mm. |

| Packaging Thickness | 0.3-15mm (depending on the available space for component placement on the circuit board) |

| Heating Power | Max6KW |

| Servo Motor Power | Traction servo motor: 1.5KW; Bag panel cutting servo motor: 0.75KW; Material feeding motor: 0.75KW; Easy-tear opening motor: 0.4KW |

| Packaging Roll Diameter | <350mm |

| Non-woven Fabric Roll Diameter | <500mm |

| Total Power Supply Capacity | 380V11.5kw |

| Air Pump Capacity | >0.25m3/min ( Bring your own) pressure:0.6-0.8Mpa |

| External Dimensions | 7500*1847*1697cm |

| Machine Weight | 2100KG |